The Application of Proximity Sensors in the Manufacturing Process of New Energy Lithium Batteries

Driven by the global energy transition and carbon neutrality goals, new energy lithium batteries have become the core power source for electric vehicles, energy storage systems and smart devices. In response to the market’s urgent demand for efficient, safe and high-precision battery production.

Ⅰ. Pain Points and Solutions in Lithium Battery Manufacturing

The production process of lithium batteries is complex, covering three major stages: the front stage (electrode preparation), the middle stage (cell synthesis), and the back stage (chemical composition, capacity formation). Each stage has extremely high requirements for precision, efficiency and consistency. The traditional production mode is confronted with the following challenges

Material deviation correction is difficult: The coating and slitting of the electrode sheet are prone to deviation, which affects the performance of the battery cell.

Low detection accuracy: Manual detection of welding defects, liquid level control, etc. is inefficient and prone to missed detections.

High safety risk: The operation of equipment in high-temperature and high-pressure environments requires real-time monitoring.

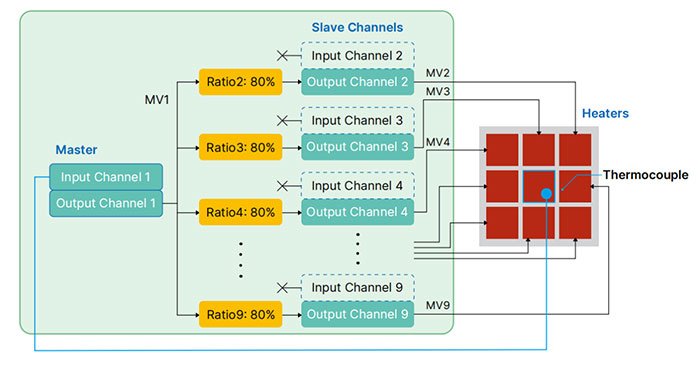

Solution: Through photoelectric sensors/inductive sensors/capacitive sensors/laser distance displacement sensors, 3D vision systems and industrial Internet of Things technology, achieve:

Material correction: ±0.2mm high-precision measurement to ensure alignment of the electrode sheets.

Welding inspection: 1μm level defect identification, missed detection rate < 1%.

Liquid level monitoring: Non-contact ultrasonic sensing to prevent electrolyte overflow.

Ⅱ. Core application Scenarios of Full-process intelligence

1. Front-end process: Electrode preparation

Coating machine deviation correction: The 3D line scanning series laser sensor can adjust the coating thickness in real time, achieving precise detection at the micrometer level.

Mixer material level detection: Ultrasonic sensors/Teflon capacitive sensors monitor the liquid level height of the slurry in real time to prevent slurry overflow.

Slitting machine control: Trough-type photoelectric sensors detect the slitting accuracy of electrode sheets, reducing material waste.

2. Mid-process: Battery cell synthesis

Winding/Stacking: The dual ultrasonic pen sensors prevent the electrode sheets from overlapping, significantly enhancing the yield of qualified products in production.

Liquid level monitoring of the liquid injection machine: Capacitive sensors for pipeline liquid level and trough-type photoelectric sensors ensure accurate liquid injection volume.

Battery discharge detection: Optical fiber sensors precisely detect the accurate feeding of materials.

3. Back-end process: PACK assembly

Top cover welding inspection: 3D line-scan laser sensor identifies weld defects, with a scanning speed of 400mm/s.

Battery in-place detection: Micro photoelectric sensors, ultra-thin capacitive sensors, precise detection of battery position on the battery production line.

Battery shell in place detection: IP67 protection grade inductive sensor and photoelectric sensor, real-time detection of material in place.

Ⅲ. Technological Advantages: Empowering Intelligent Manufacturing

High precision: The resolution of the laser displacement sensor can reach up to 1μm, and the accuracy can reach up to 10μm, meeting the process requirements of 50μm grade.

Strong stability: Adaptable to various temperature environments (-25℃ to 70℃), anti-vibration design, suitable for harsh production line environments.

Intelligentization: IO-Link technology enables data interconnection and builds a digital quality traceability system.