Delta Redundant PLC AH500: Strengthening the “zero interruption” operation defense line of tunnel monitoring system

The monitoring system of a separated long tunnel in East China (with two-way four lanes, a single tunnel line length of over 7,500 meters, and a designed speed of 80km/h) has been upgraded and renovated to the standard of an intelligent operation and maintenance center. The system controller is required to have multiple capabilities such as super computing power, adaptability to extreme environments, convenient maintenance, and compatibility with multiple devices.

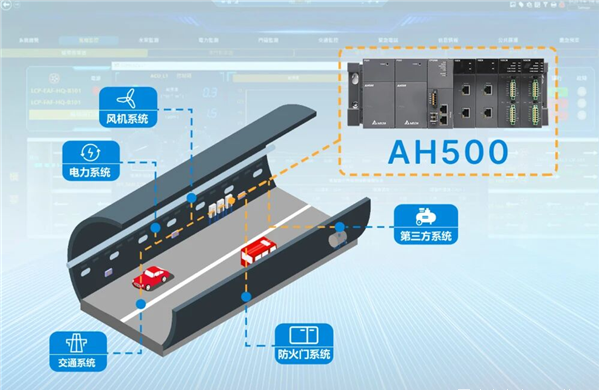

After multiple rounds of technical verification and engineering practice, only Delta’s redundant PLC AH500 precisely meets the core demands of the design unit for the controller. As the “nerve center” of the system, it builds a solid technical defense line for safe and efficient operation.

Core design requirements

Based on the characteristics of tunnel engineering and the trend of intelligent development, the functional role of the tunnel monitoring system has undergone significant changes this time. It has evolved from a single “electronic eye” to one that integrates multiple operation and maintenance responsibilities such as traffic dispatching, environmental monitoring, equipment control, and emergency response. Therefore, the tunnel planning and design unit has put forward clear requirements for the controller:

Super computing power and redundancy guarantee: The controller needs to handle complex tasks such as multi-source data fusion and multi-system collaborative control, and must have high-performance processing capabilities with millisecond-level response. At the same time, it ensures “zero interruption” operation through designs such as dual-machine hot standby and module redundancy.

Extreme environmental adaptability: In response to the harsh conditions such as high temperature and humidity, dust and vibration, and electromagnetic interference in the enclosed space of tunnels, the controller must meet industrial-grade protection standards and have the ability to operate stably for a long time against aging and corrosion.

Maintenance convenience: As tunnel operation and maintenance prohibit prolonged network and power outages, all functional modules of the controller must adopt an integrated metal bus base plate design, supporting hot-swapping replacement to ensure continuous system operation without being affected.

Compatibility and openness: In response to the access requirements of multiple brands of equipment such as transportation, fire protection, and power, the controller needs to have flexible protocol conversion and interface expansion capabilities to support the parallel management requirements in intelligent scenarios.

1: Redundant architecture, seamless switching within 20ms

The AH500 adopts a complete redundant architecture featuring dual cpus, dual main and backplanes, dual power supplies, and dual communications. It supports regional expansion capabilities, which can simplify the system architecture and reduce the costs of wiring and software and hardware configuration. When the main controller fails, the backup controller can take over seamlessly within 20 milliseconds to ensure that the monitoring is not interrupted. Combined with the dual-fiber self-healing ring network, data can be efficiently uploaded to the toll station and section monitoring center, achieving the coordination of remote control and local control.

2: Industrial-grade design, conquering harsh environments

The AH500 has a wide-temperature operation capability and is not affected by temperature fluctuations inside the tunnel. The G3 protective coating meets requirements such as dust prevention and moisture resistance, significantly reducing the risk of equipment aging in harsh environments. There is no risk of shutdown during continuous operation, ensuring the reliability of the system under extreme conditions (such as high temperature and vibration).

3: Supports hot plugging, plug-and-play without downtime

The AH500 mainframe and related modules all adopt a hot-insertion replacement design, allowing for the replacement of faulty modules without the need to shut down the machine. After the replacement is completed, the new module will automatically return to its normal working state without the need for the user to manually set or switch the state.

4: Efficient Interaction among multiple subsystems activates “Intelligent Collaboration”

The AH500, with its powerful multi-task processing and expansion capabilities, deeply integrates emergency phone and broadcasting systems, video patrol systems, etc. The main controller upgrades the integrated collaborative mode through multi-task processing (call control, resource allocation, protocol processing, route authentication, etc.). Even if the network of the main control server is interrupted, it can still ensure offline call functions and safeguard driving safety.

Practical application effect

Real-time visibility of equipment status: The status of all mechanical and electrical equipment is clear at a glance, and system operation and maintenance are clear and controllable.

Component replacement within seconds: The long-term operation of the controller is guaranteed, and old and damaged modules can be replaced within seconds.

The system operates stably and reliably: The monitoring system is not affected by environmental conditions and maintains a good operating condition for a long time.

Deep collaboration among multiple subsystems: Subsystems such as transportation, ventilation, and fire protection have shifted from operating independently to efficient coordination, marking a new level of overall operation and maintenance efficiency.

Delta AH500 redundant PLC, with its dual insurance design, industrial-grade reliability and intelligent interlocking capabilities, has solved the operation and maintenance challenges of tunnel monitoring, making tunnel operation safer and providing a replicable successful experience for the industry.