The working principle of an oxygen detector

Working principle

·Electrochemical principle: By taking advantage of the electrochemical reaction between oxygen and electrolyte at a specific electrode, a current proportional to the oxygen concentration is generated. The oxygen concentration is determined by measuring the current. This type of sensor based on this principle has the advantages of high precision, good stability and fast response speed, and is suitable for oxygen detection in various environments.

· Paramagnetism principle: Based on the paramagnetism of oxygen, when oxygen enters a magnetic field, it is subjected to the force of the magnetic field. The concentration of oxygen can be calculated by measuring the magnitude of this force. The detector based on this principle has high measurement accuracy and is not disturbed by other gases. However, the instrument is relatively large in size and is often used in high-precision detection scenarios.

·The principle of zirconia: At high temperatures, when the oxygen concentrations on both sides of zirconia are different, oxygen ions will migrate, forming a potential difference. This potential difference has a linear relationship with the logarithm of the oxygen concentration. The oxygen concentration can be calculated by measuring the potential difference. It is applicable to oxygen detection in high-temperature environments, such as industrial furnaces and kilns.

Structural composition

· Sensor: The core component is responsible for sensing oxygen and converting it into an electrical signal. Sensors based on different principles have different structures and performances. For example, an electrochemical sensor is composed of a working electrode, a counter electrode, a reference electrode and an electrolyte, etc. Paramagnetic sensors have special magnetic field generating devices and detection components. Zirconia sensors are mainly composed of zirconia probes and heating elements, etc.

·Signal processing circuit: It processes the weak electrical signal output by the sensor through amplification, filtering, linearization and analog-to-digital conversion, converting it into a recognizable digital signal or standard analog signal for subsequent display and transmission.

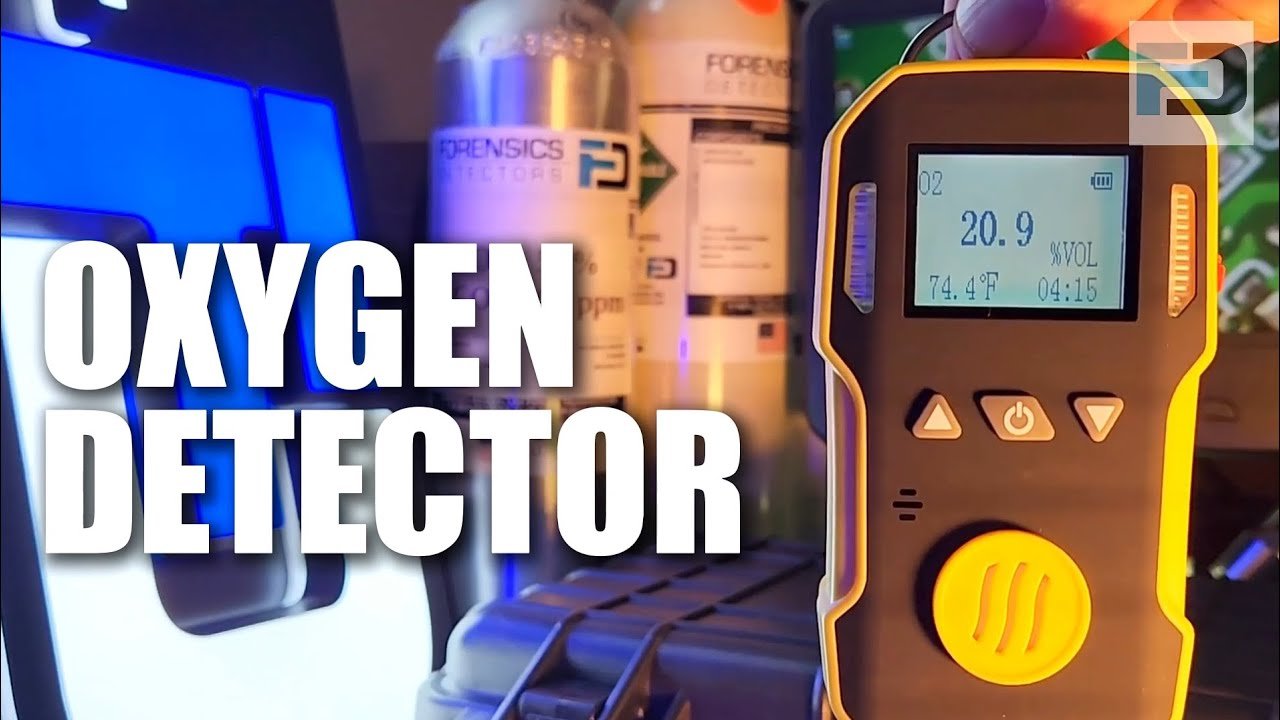

· Display module: Usually a liquid crystal display (LCD) or digital tube, it is used to visually display the current detected oxygen concentration value. Some can also show relevant status information, such as battery power and alarm status.

· Alarm module: When the detected oxygen concentration exceeds the preset safety range, it will issue an audible and visual alarm signal to remind the user to take corresponding measures. The alarm methods can be sound alarm, flashing light alarm or vibration alarm, etc. Some high-end instruments can also send alarm information remotely via text messages, the Internet and other means.

· Power module: It provides power for the detector. Common power sources include batteries (such as lithium batteries and alkaline batteries) and AC power adapters. Some portable oxygen detectors are equipped with rechargeable batteries, which are convenient to carry and use. Fixed detectors are mostly powered by AC power to ensure continuous and stable operation.

· Shell: Protects the internal components, featuring excellent sealing and protective performance, and can adapt to various working environments, such as waterproofing, dustproofing, and explosion-proofing. The shell material is usually high-strength plastic or metal to ensure the instrument’s sturdiness and durability.

Characteristics and Applications

· Characteristics

High-precision measurement: It can accurately measure the oxygen content in the environment, with an accuracy of ±1% or higher, meeting the precise requirements for oxygen concentration detection in different scenarios.

Fast response: It can respond to changes in oxygen concentration within a short period of time, providing accurate detection data promptly for real-time monitoring of environmental oxygen conditions.

Multiple detection functions: In addition to the basic oxygen concentration detection, some detectors also have other functions, such as settable lower and upper detection limits, data recording and storage, average value calculation, maximum and minimum value recording, etc., which facilitate users to analyze and manage the detection data.

Portability and flexibility: The portable oxygen detector is small in size and light in weight, making it easy to carry and allowing for detection anytime and anywhere. Fixed oxygen detectors can be installed at specific locations to achieve long-term continuous monitoring of specific areas. In addition, some oxygen detectors can be integrated with other devices, such as gas detection systems and safety monitoring systems, and have strong flexibility.

“Application”

In the industrial field, it is used in industries such as chemical engineering, petroleum, natural gas, and coal to detect the oxygen concentration during the production process, preventing safety accidents such as explosions and fires caused by excessively high or low oxygen concentration. It can also be used to optimize production processes and enhance production efficiency. For instance, in petrochemical plants, the oxygen concentration inside equipment such as reaction vessels and storage tanks is detected to ensure the safe operation of the equipment. In underground coal mines, the oxygen content in the tunnels is detected to ensure the life safety of miners.

Environmental monitoring: It is used to monitor the oxygen concentration in the atmospheric environment, indoor air quality, sewage treatment plants, landfill sites and other places. For example, in urban environmental monitoring, understanding the changes in oxygen content in the air and assessing air quality; In indoor environments, detect whether the oxygen concentration meets the human health standards and promptly identify problems such as poor ventilation. During the sewage treatment process, monitor the oxygen concentration in the aeration tank and optimize the sewage treatment process.

In the medical field, it is used in hospital wards, operating rooms, intensive care units and other places to monitor the oxygen concentration in the respiratory environment of patients, ensuring the safety and effectiveness of oxygen therapy for patients. Meanwhile, during the anesthesia process, accurately monitoring the oxygen concentration is an important measure to ensure the life safety of patients. In addition, some portable oxygen detectors can also be used for self-monitoring of patients undergoing home oxygen therapy.

In the aerospace and military fields: Monitor the oxygen concentration in aircraft cabins and spacecraft cabins to ensure the breathing safety of astronauts and passengers. In the military field, it is used for battlefield environment monitoring, air quality testing within military facilities, and personal protection of soldiers, etc.

Today, whilke I was at work, my cousin stole my apple ipad

and testerd to see if it can survive a twenty five foot drop, ust soo she can be

a youtube sensation. My apple ipazd is now destroyed and

she hass 83 views. I know this is totally off topic but I had to shate it with someone!