What is a Servo Motor Encoder? Key Points for Technical Selection and Common Issues

I. What is a Servo Motor Encoder?

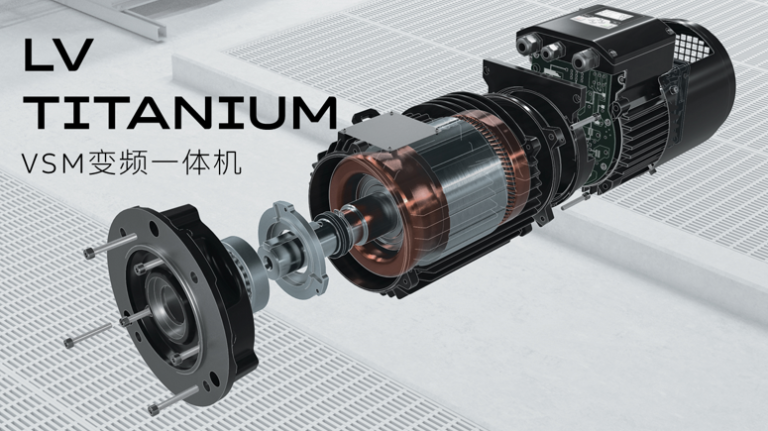

A servo motor encoder is a core feedback component in a servo system. It is used to detect parameters such as the rotational speed, position, and angle of the motor in real time and feed the signals back to the controller (such as a servo drive), forming a closed-loop control to ensure the accuracy and stability of the motor’s movement. Its core functions include:

- Position feedback: Determining the absolute or relative position of the motor shaft.

- Speed feedback: Monitoring the rotational speed of the motor to achieve speed closed-loop control.

- Direction identification: Judging the rotation direction of the motor.

II. Main Types of Encoders

According to the working principle and output signal type, encoders can be classified into the following categories:

- Classification by Signal Type

| Type | Characteristics | Application Scenarios |

|---|---|---|

| Incremental Encoder | – Outputs pulse signals (orthogonal pulses of phase A and B, zero pulse of phase Z). <br> – The position needs to be calculated by accumulating pulses. <br> – Low cost and simple structure. | General servo systems, rotational speed monitoring. |

| Absolute Encoder | – Each position corresponds to a unique code (such as binary, Gray code). <br> – Directly outputs the absolute position without accumulation. <br> – The position is not lost after power off. | High-precision positioning, multi-axis synchronization, power-off memory. |

| Hybrid Encoder | – Combines the advantages of incremental and absolute encoders. <br> – The main output is an incremental signal, and the auxiliary output is an absolute position signal. | Mid- to high-end applications that balance accuracy and cost. |

- Classification by Detection Principle

- Optical Encoder: Detects pulses through a grating disk and photosensitive elements. It has high accuracy (resolution can reach tens of thousands of lines), but is vulnerable to dust and oil contamination and requires regular maintenance.

- Magnetic Encoder: Detects the position by using the change of magnetic field. It has strong resistance to vibration and dust and is suitable for harsh environments (such as industrial sites, machine tools), but temperature drift may affect the accuracy.

- Resolver: Based on the principle of electromagnetic induction, it outputs analog signals and has extremely strong anti-interference ability. It is commonly used in high-reliability scenarios (such as servo motors, robot joints).

III. Key Technical Parameters

- Resolution (number of lines): The number of pulses output per revolution (such as 2500 lines, 17-bit absolute encoder), which directly affects the accuracy of position control.

- Response frequency: The maximum rotational speed at which the encoder can stably output signals. For high-speed scenarios, a model with a high response frequency needs to be selected.

- Output mode: Voltage type (such as TTL, HTL): Suitable for short-distance transmission. Differential signals (such as RS422, Sin/Cos): Strong anti-interference ability and suitable for long-distance transmission.

- Protection level: Such as IP65, IP67, which determines the reliability of the encoder in dusty and liquid environments.

- Operating temperature: Industrial grade is usually from -40°C to +85°C. For special scenarios, a wide-temperature model needs to be customized.

IV. Typical Application Scenarios

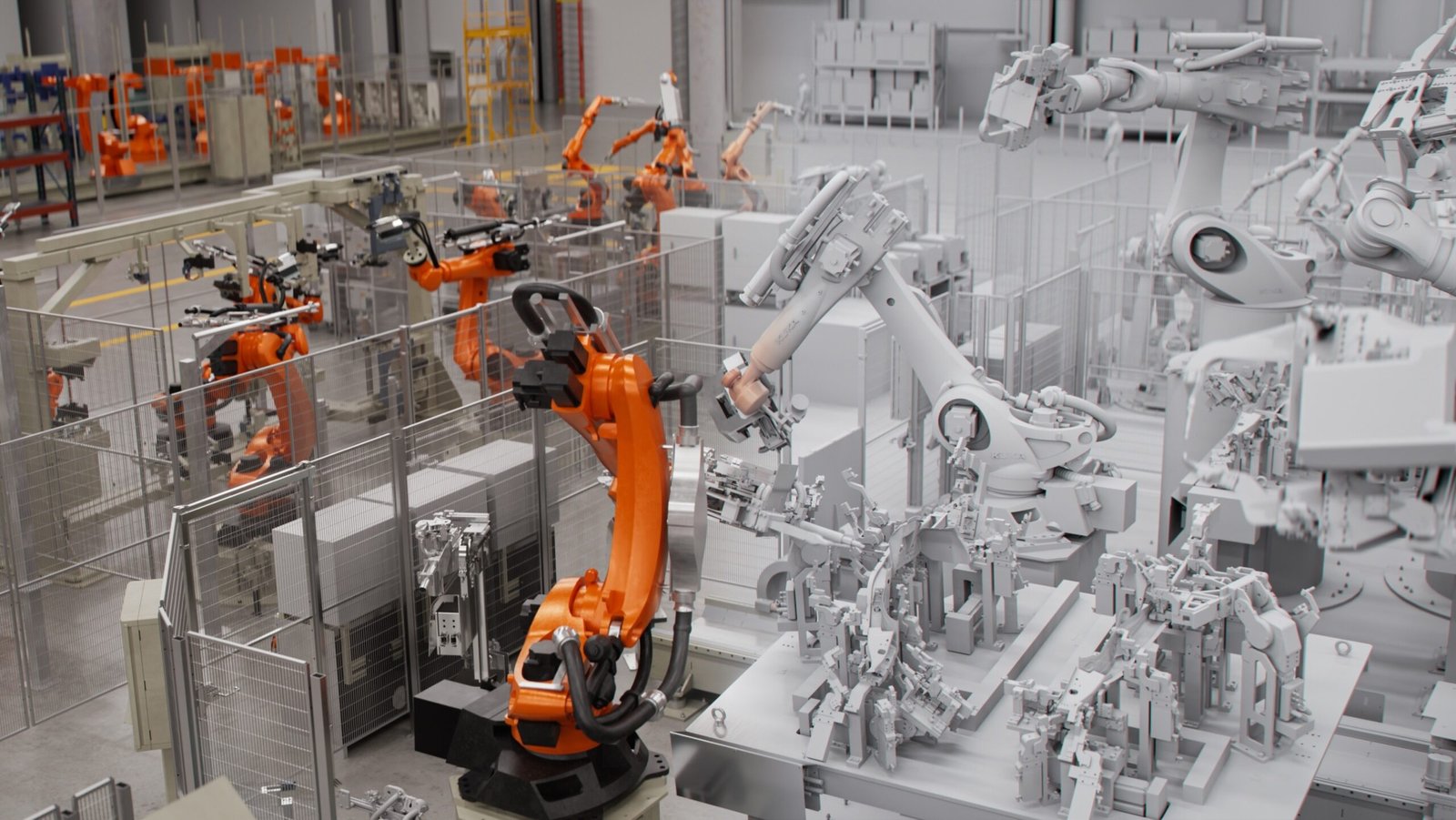

Precise positioning and trajectory control are achieved through absolute encoders and are applied to multiple fields such as industrial robots, motor drive systems, automated production lines, intelligent logistics equipment, semiconductor manufacturing, and medical equipment.

V. Key Points for Selection and Common Issues

- Key Points for Selection:

- Accuracy requirements: For high-precision scenarios, choose an absolute encoder or an incremental encoder with a high number of lines.

- Environmental conditions: In dusty/vibrating environments, give priority to magnetic encoders. In oil-contaminated scenarios, optical encoders need enhanced protection.

- System compatibility: Confirm that the output signal of the encoder matches the interface of the drive (such as differential input, single-ended input).

- Common Issues and Solutions:

- Signal interference: Use shielded wires, differential signal transmission, and grounding treatment.

- Position loss: Incremental encoders need to be combined with a home return program; for absolute encoders (if battery-powered), check the battery power.

- Mechanical installation: Ensure the concentricity of the shaft and avoid axial/radial impact forces that may damage the encoder.