Why should a dedicated temperature controller be used instead of a general PLC for precise temperature control (±0.1℃)?

If PLC can also achieve high-precision control, why not choose it? This involves considerations such as hardware architecture, algorithm design, and the ease of use of the entire system.

In the field of industrial temperature control, when the precision requirement is raised to ±0.1℃ or even higher, such as in industries like semiconductor manufacturing and precision material processing, an increasing number of people tend to choose dedicated temperature controllers rather than traditional PLCS.

High precision is only the first hurdle

When it comes to the commonalities between PLCS and dedicated temperature controllers for temperature control, whether it is a temperature controller or a PLC, PID control is one of the most widely used principles.

In scenarios where the accuracy requirement for temperature control is low, the traditional single PID is indeed more than sufficient. However, when confronted with more complex situations, such as chip etching and thin film deposition in semiconductor manufacturing, it becomes inadequate because:

■ On the one hand, the semiconductor manufacturing process requires extremely high sampling rates, measurement accuracy and display accuracy, etc. Usually, the display accuracy is required to reach at least 0.01℃, and the temperature control accuracy is even less than 0.1℃. In some scenarios, it even needs to reach 0.05℃.

■ On the other hand, the characteristics of semiconductor manufacturing equipment itself can hinder the accuracy of temperature control. For example, heating furnaces complete the temperature increase through thermal radiation, which has obvious lag. It is very easy to cause temperature overshooting or untimely adjustment, thereby affecting the product quality.

The extremely high precision requirements have left most PLC products far behind. Even after hardware upgrades, most PLCS still find it difficult to stably meet such high precision standards.

Of course, apart from the difficulty in improving accuracy, to reduce temperature measurement and reading errors and address the lag of the heating system, it is also necessary to introduce better algorithms, including PID cascade control, feedforward control, and the introduction of AI temperature control algorithms, etc.

■ For the same accuracy, the “hidden cost” of general-purpose PLCS is higher

Let’s assume for the time being that the hardware conditions of a PLC have met the standards – for instance, some high-end performance PLCS have a sampling period of 10ms and an ADC resolution of over 16 bits. The parameters seem close to those of a dedicated temperature controller, but when encountering some nonlinear, large lag, and multi-variable coupling temperature control scenarios, these shortcomings will be magnified:

■ From “0” to “1”, algorithm development is not easy

The essence of some PLCS is a universal control platform. The core algorithms such as cascade PID and feedforward compensation built into the dedicated temperature controller need to be completely dependent on the user to write and debug the parameters themselves in the PLC, which places a high demand on personnel.

■ The cost of debugging and trial-and-error is too high

The temperature control program of PLC is highly dependent on manual parameter adjustment. PID parameter tuning in complex scenarios (such as temperature overshoot suppression in semiconductor etching furnaces) requires talents with multi-disciplinary knowledge and rich experience.

Generally speaking, the debugging cycle of the feedforward algorithm alone is as long as 2 to 3 weeks. These are all “hidden costs” that cannot be ignored, and the parameter adaptability is poor. After replacing the equipment, it needs to be redeveloped. This is in sharp contrast to the “plug and play” function of the dedicated temperature controller.

Technology solidification and Encapsulation – From “general-purpose” to “Specialized”

Overall, although the open architecture of PLC is flexible, when it comes to precise temperature control, the advantages of dedicated temperature controllers, in addition to the basic functions of high precision and high reliability, also solidify the solutions to common industry problems into a “knowledge base”, which can significantly reduce the personnel, financial and time input costs of enterprises in an intangible way.

For instance, Delta’s recently launched DTDM series modular temperature controllers feature outstanding hardware specifications and self-developed algorithms, and their performance can already rival that of leading foreign products. Some of the designs for precise temperature control applications have reference value for understanding the development of temperature control technology:

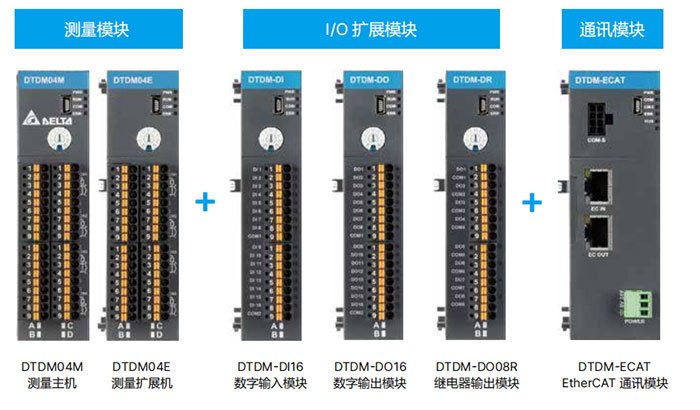

■ The hardware adopts a modular design

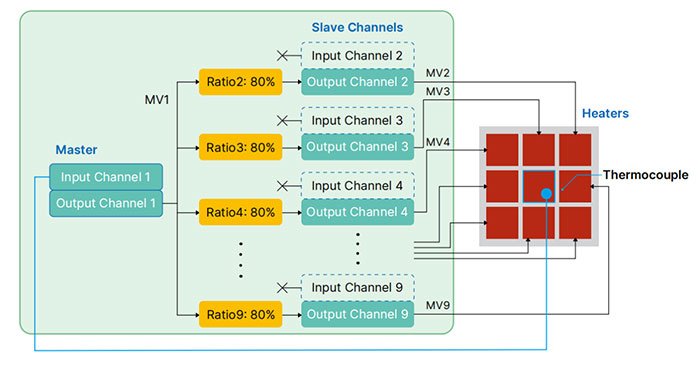

Delta’s DTDM series temperature controllers adopt a flexible modular design, featuring 4 channels and 2 cascade PID circuits. A single DTDM group can be connected in series with up to 8 measuring machines for 32 PID controls.

In this way, users can freely combine the measurement host, measurement expansion machine, digital input and output module, and communication module according to actual needs. Therefore, whether it is a simple or complex functional application, it can be called up at will.

The sampling period of the product has been compressed to 10ms. With the built-in temperature correction line chart, it can provide 14 sets of temperature correction points and two compensation methods: turning points or offsets, which can effectively eliminate errors and ensure the accuracy of the measurement.

■ The control algorithm is encapsulated in advance

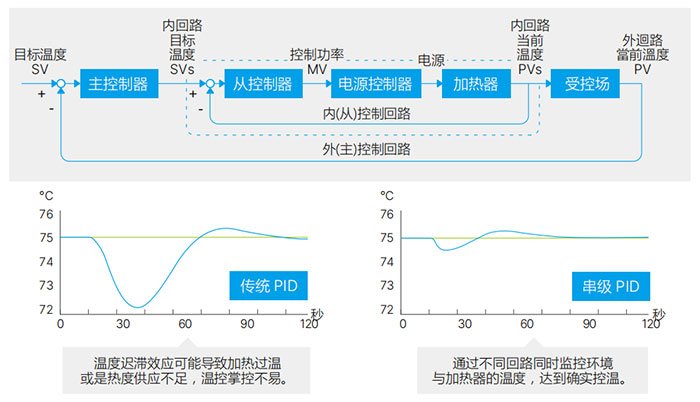

Cascade PID control: Solving the problem of lag

The DTDM series temperature controller operates the external/internal (master/slave) control circuits in series. The main controller outputs control signals based on the deviation between the target temperature and the actual temperature, while the slave controller controls the heating equipment according to the set value. The collaboration of the two can quickly eliminate the temperature drop caused by hysteresis or other interferences, achieving stable temperature control.

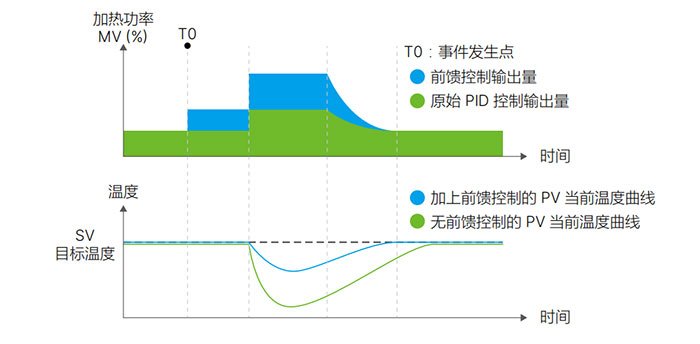

Feedforward compensation: An advanced response to dynamic disturbances

For the temperature disturbance conditions of special heating equipment, feedforward control can pre-compensate for the known heat loss at the moment when the temperature change is detected, and make advance adjustments to reduce the temperature change. Compared with PLC products, the feedforward compensation function of the DTDM series temperature controller can ensure temperature stability and improve product quality in processes such as semiconductor dry etching.

■ Pre-adaptation for specific process scenarios

Nowadays, many thermostat manufacturers will integrate industry-specific control algorithms based on the process characteristics of specific industries (such as semiconductor etching, thin film deposition, and lithium battery sintering). For example, during the process of product research and development, Delta attaches great importance to integrating the industry Know-How optimization algorithm.

The DTDM series is particularly suitable for semiconductor wafer processing equipment, such as chemical vapor deposition systems (CVD), physical vapor deposition systems (PVD), oxidation diffusion furnaces, silicon etching machines, atomic layer deposition systems (ALD), etc. In the future, Delta will also continue to work with industry users to continuously enrich the functions of its product series and carry out more customized development.

Summary

The reason why dedicated temperature controllers are irreplaceable is that in the context of “precise temperature control”, control technology needs to move from “general-purpose” to “specialized”, and from “makeshift” to “more precise”.

Reliable and flexible hardware, pre-encapsulated algorithms, and scenario-based application – this is precisely why when precise temperature control is needed, people tend to use dedicated temperature controllers rather than general-purpose PLCS!